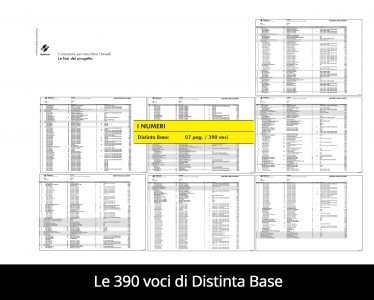

Design and machine tools

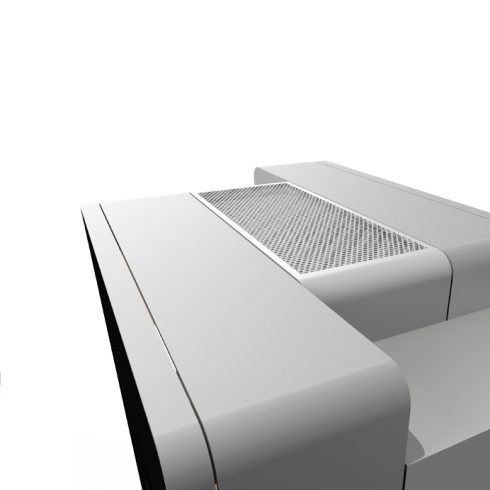

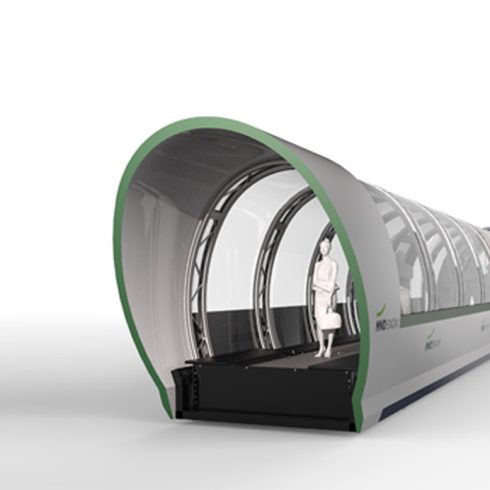

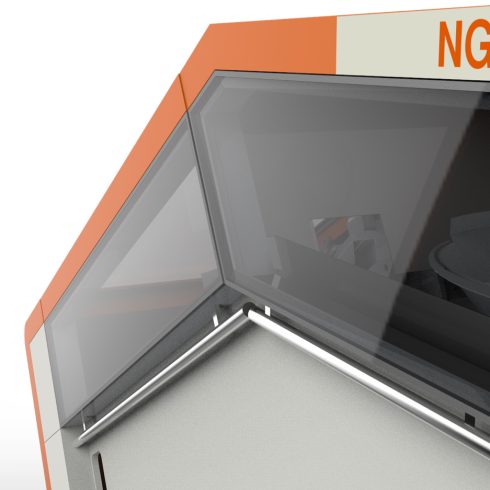

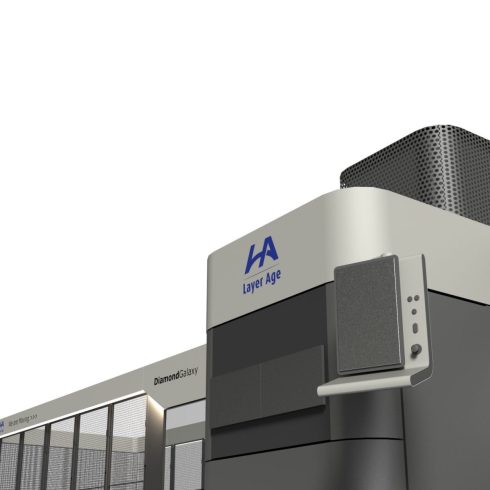

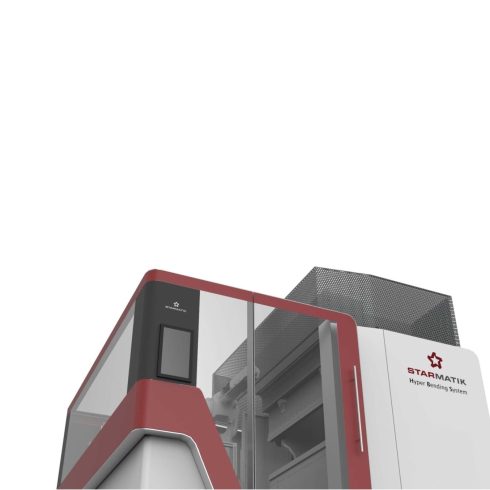

When we talk about design in this industrial sector, we basically refer to the bodywork of the machine tool, therefore to the need to “enclose” moving parts in an attractive aesthetic form.

It is an intervention that can be defined as necessary in function and discriminating in form, in an area where the role of design does not concern so much aesthetics in itself, as well as the coherent representation of the quality of the content (the car) through the quality of the container (the bodywork).